Grips and assembles components with surgical precision.

Autonomously avoids obstacles and plans routes in the factory.

Easy tool and task changes in minutes.

Learns continuously to work faster and faster.

Battery replacement without work interruption (Hot-Swap).

2 h

230 kg

2 kWh

770(L) * 620(W) * 1630(H) mm

0-45°C

5 kg

7

0-2 m

5 h, supports hot-swap battery replacement

2 h

230 kg

2 kWh

770(L) * 620(W) * 1630(H) mm

0-45°C

5 kg

7

0-2 m

5 h, supports hot-swap battery replacement

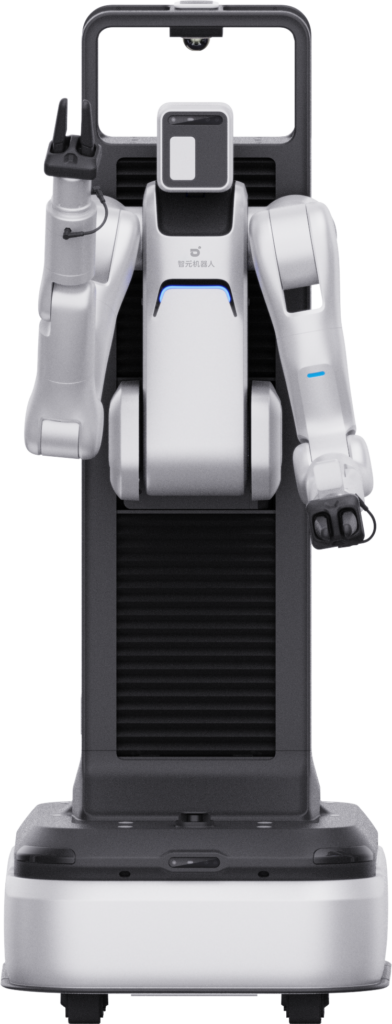

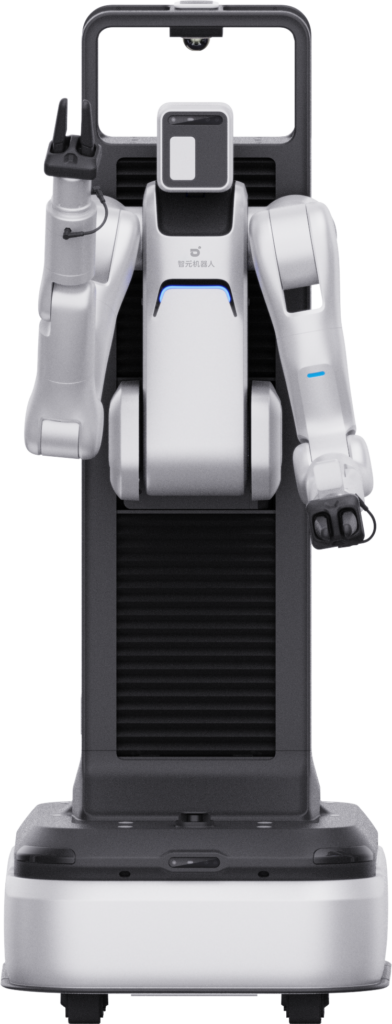

Two arms with 7 degrees of freedom each. Work together or independently, smoothly passing objects to each other and handling complex components

4-wheel drive with zero turning radius and "crab walk" mode. Mobile torso (22 degrees of freedom) allows the robot to reach any location in human workspace.

Integrated chassis, arms, and sensor design enables full robot deployment in just 24 hours.

With 275 TOPS computing power, the robot recognizes objects and makes operational decisions in fractions of a second (milliseconds).

Using 3D models and reinforcement learning reduces robot adaptation time to new objects to just a few hours.

Integrated chassis, arms, and sensor design enables full robot deployment in just 24 hours.

With 275 TOPS computing power, the robot recognizes objects and makes operational decisions in fractions of a second (milliseconds).

Using 3D models and reinforcement learning reduces robot adaptation time to new objects to just a few hours.

Modular design enables remote updates (OTA), allowing the robot to continuously learn new skills.

AI algorithms self-optimize based on collected data, increasing efficiency with each day of operation.

Integrated simulation and training system enables lightning-fast testing and implementation of new features.

360° LiDAR, 4 AI vision sensors, and 2 force sensors work together to detect obstacles in milliseconds.

Arm collision detection system and redundant control ensure the highest level of safety when working with humans.

Supports battery replacement during operation and autonomous charging, eliminating downtime.

Built-in real-time self-repair mechanisms minimize the need for manual servicing.

Wypełnij prosty formularz bądź napisz do nas bezpośrednio na WhatsApp.

Fill out a simple form or write to us directly on WhatsApp.